Keeping track of materials is enormously important in production processes, but that is not your core business as a manufacturer. With Wolf we help you focus on your core business, but also be on top of your stock levels, material waste, and help your communication with logistical partners along.

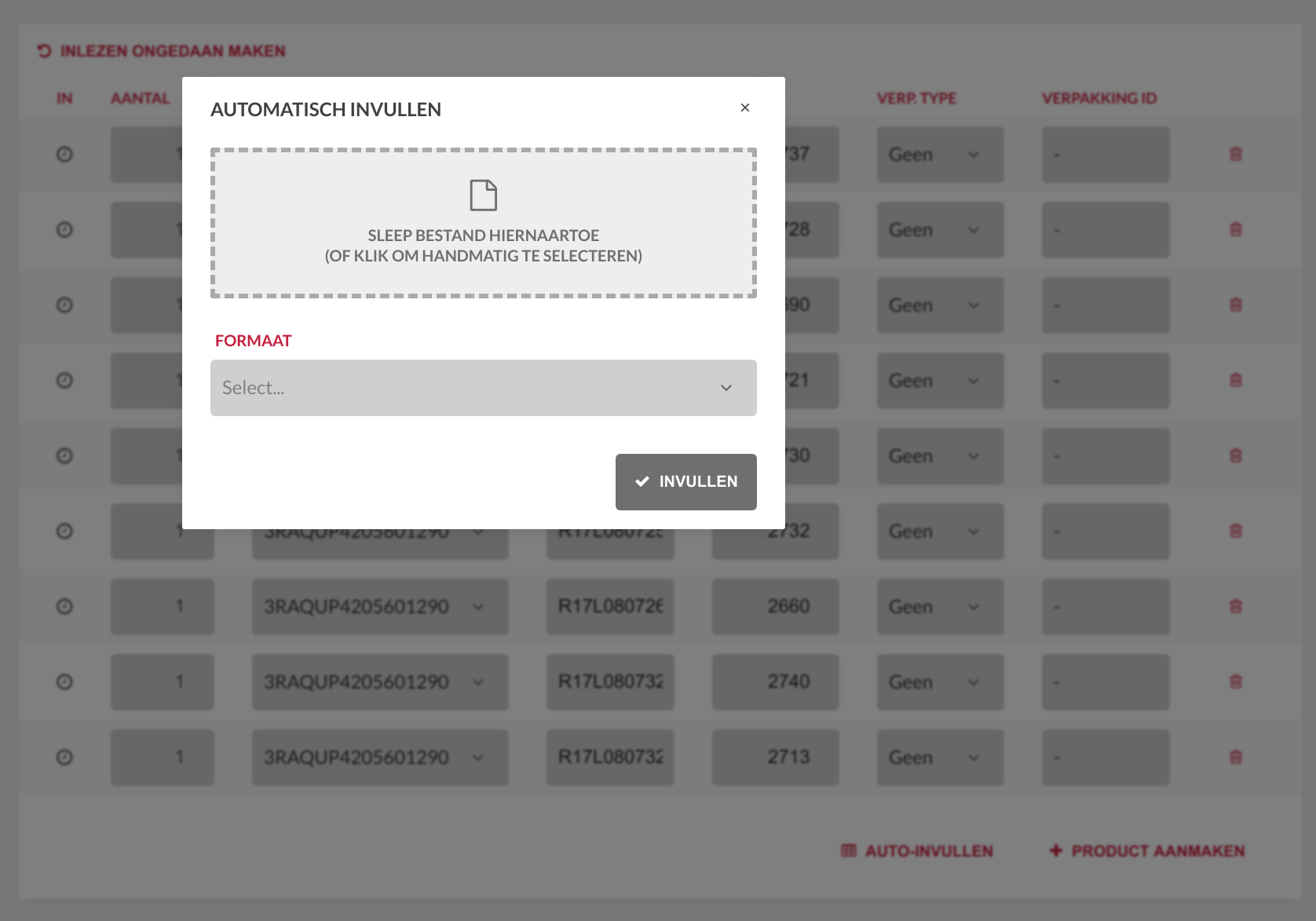

Communicating with your logistical partners has never been easier. Gone are the days of e-mailing excel files back and forth.

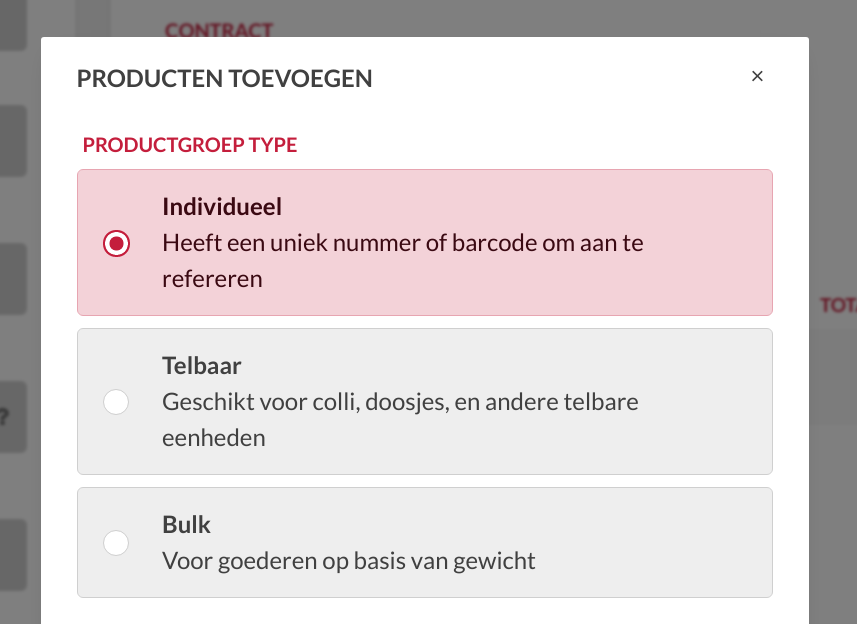

We can handle any type of product, from raw materials to boxes with thousands of parts. Defining production processes with many different types of materials is not a problem at all.

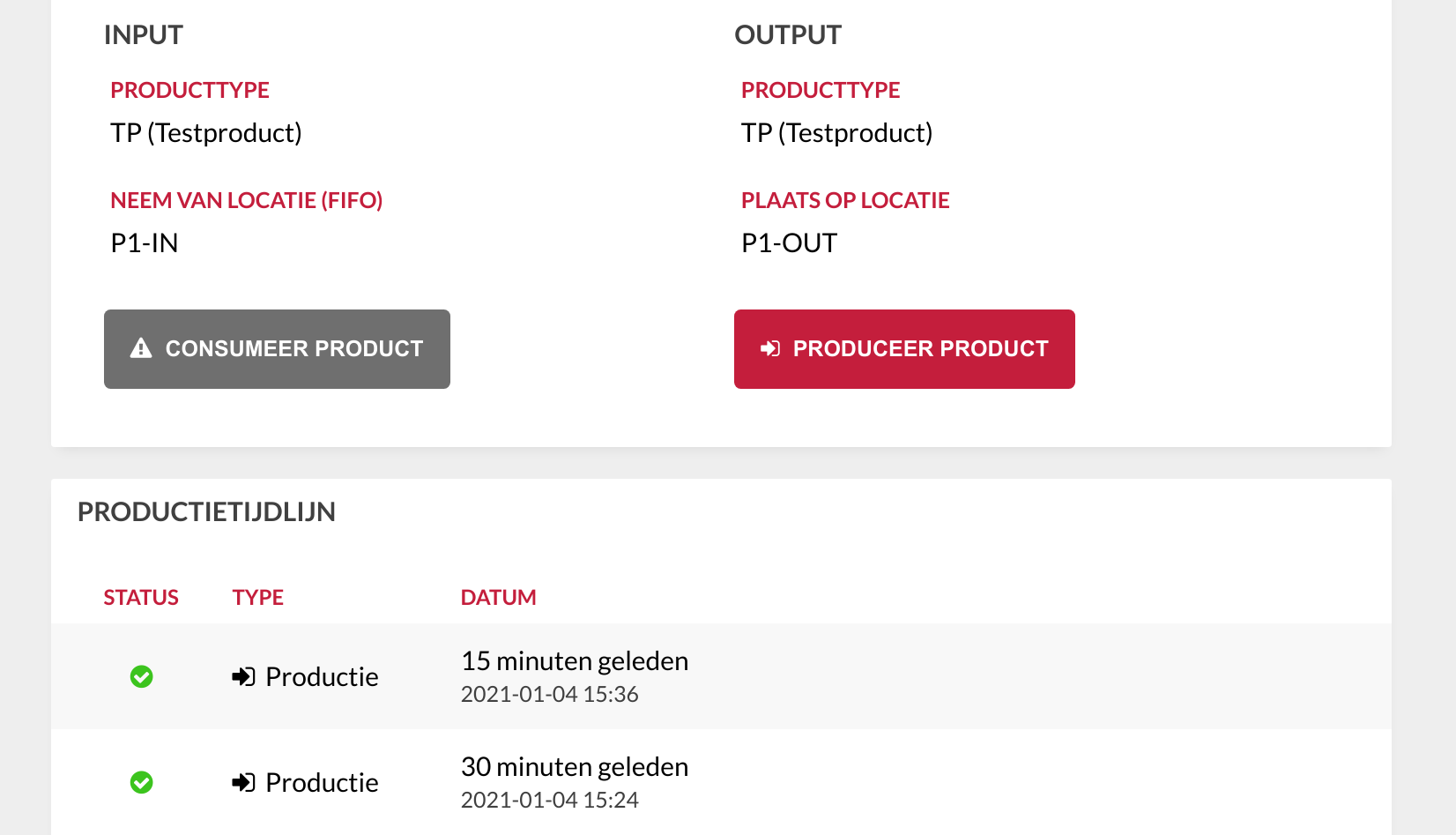

Let your production processes drive your logistics: automatically get raw materials from stock, put finished materials into the staging area or mark them as ready for transport to the customer.

Requesting materials by hand is an option, but we can also interface with ERPs or integrate automation in the factory to eliminate manual intervention.

Gone are the days of clunky hand scanners with incomprehensible interfaces. Our software runs on:

With support for scanner peripherals.

Without complex installation or update processes.

We would love to think along about your use cases! Do not hesitate to contact us.